Russia, Belarus Create New Technology for Alternative Energy

12:41 GMT 11.08.2022 (Updated: 12:42 GMT 11.08.2022)

© Photo : MIET Press Service, Ilya Gavrilin

Subscribe

Researchers at the National Research University of Electronic Technology “MIET”, jointly with colleagues from Belarus, have created a simple and safe method to create silicon germanium films that can turn waste heat from industrial facilities into electricity.

Silicon-germanium alloy films make a promising material for thermoelectric converters, with high stability and efficiency even at temperatures of 800-1100 Celsius. Scientists explained that these films can be used to convert waste heat in metallurgical production facilities, nuclear power plants, and other industrial facilities where high-temperature processes take place into electric power.

Scientists at the National Research University of Electronic Technology (MIET), working together with colleagues from the Belarusian State University of Informatics and Radioelectronics (BSUIR), have developed a new method of producing silicon-germanium film structures, which they claim to be much easier and safer than analogs. Their research results were published in the Materials Letters journal.

“The approaches used today to create silicon-germanium alloy films have a number of problems and require compliance with special conditions, which hinders the widespread introduction of this material. Our methodology is designed to solve this problem,” said Ilya Gavrilin, associate professor at the Institute of Advanced Materials and Technologies of the National Research University MIET.

The developed method makes it possible to control the concentration of germanium in a wide range, thus enabling the creation of an alloy with optimal properties, the authors of the study noted. This could be achieved by controlling the porosity of the alloy's second element, silicon.

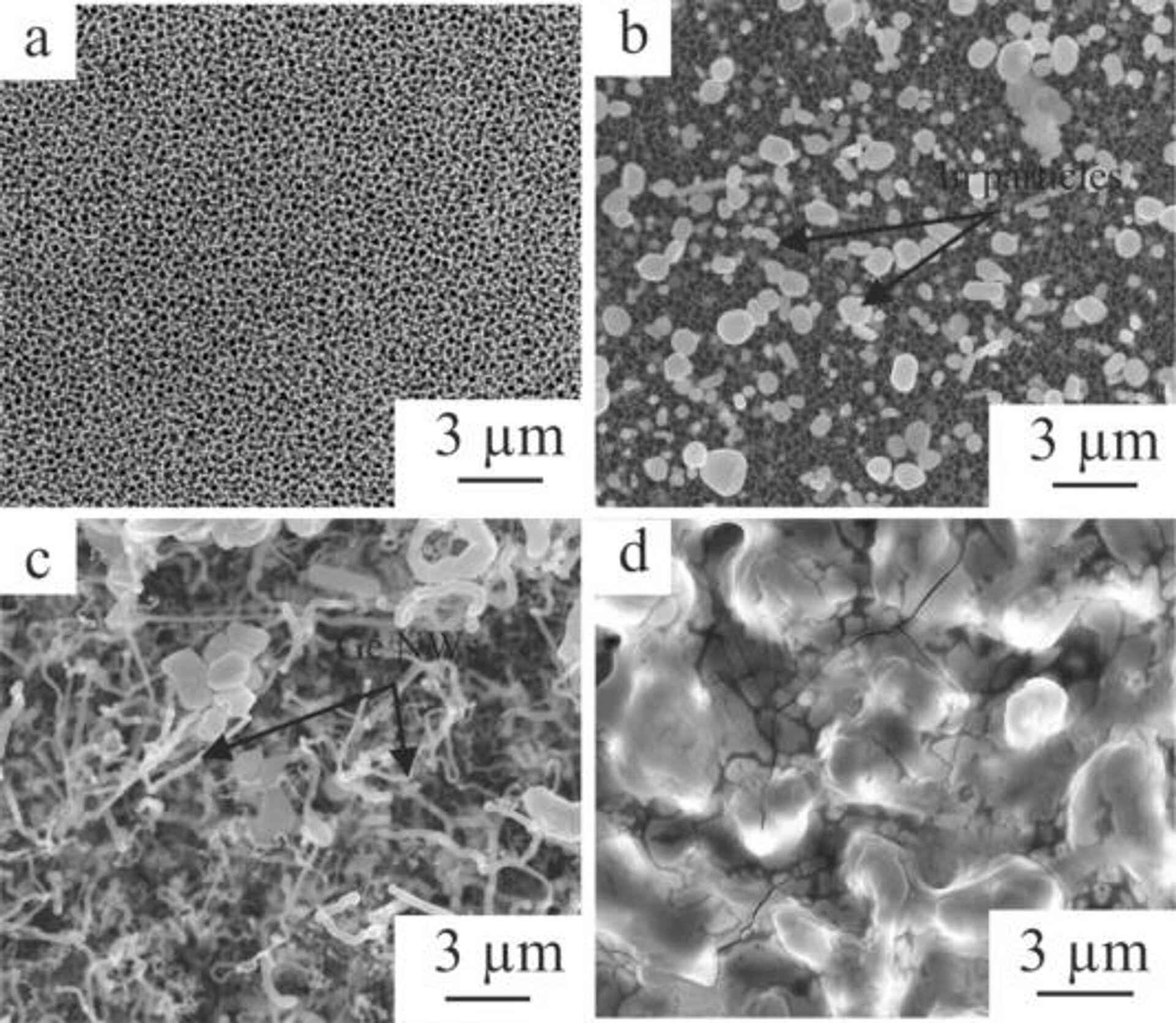

SEM images of Si1-xGex film morphology at different stages of its formation: (a) porous silicon, (b) indium particles, (c) germanium nanofibers, (d) Si1-xGex film.

© Photo : MIET Press Service, Ilya Gavrilin

According to the scientists, the proposed approach will expand the scope of application of such films. For example, they will be in demand in the production of photodetectors and solar energy elements.

“This technique is based on our university's recently-discovered ability to produce germanium via the electrochemical reduction of germanium dioxide from aqueous solutions on fusible metal particles. Currently, there exist no published analogues of our technology for creating films from this alloy,” noted Ilya Gavrilin.

The study was carried out within the framework of Russian Science Foundation (RSF) Grant No. 20-19-00720. At the next stage, the research team intends to continue studies of the optical, electrical, and thermoelectric properties of the produced films.

The National Research University of Electronic Technology MIET is working in this area within the framework of the "Priority 2030" state program of the Ministry of Science and Higher Education of the Russian Federation.