A team of scientists from the Russian National Research Technological University MISIS (NUST MISIS) have managed to improve the technology for alumina 3D printing, which helps increase the hardness of materials by at least one and a half times.

The study titled "In-situ synthesis and characterisation of powdery nanocomposite carbon nanotubes/nanoalumina" was published in the journal Composites Communications.

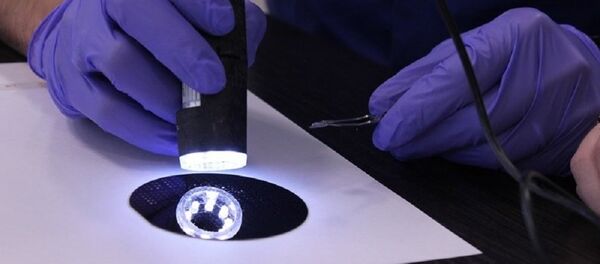

In the research, MISIS scientists pointed to the development of a special nano carbon additive that makes it possible to improve the quality of 3D-printed aerospace composite materials.

NUST MISIS professor Alexander Gromov, in turn, said that the scientists were able to improve the "properties of [3D] printing powder" by "changing its chemical and phase composition and introducing additional components into the main matrix".

Gromov referred to carbon nanofibres with high thermal conductivity, which he said adds to minimising "temperature gradients between printed layers during the synthesis of products, at the selective laser melting stage".

According to him, this helps to prevent a lack of homogeneity in the microstructure of the material.

The study was carried out jointly with specialists from the Siberian Branch of the Russian Academy of Sciences.

In the future, NUST MISIS's research team plans to determine the optimal conditions for selective laser melting of new composite powders, as well as to develop a technology for post-processing and industrial use of synthesised products.