Question: NUST MISIS has become the first university to launch a national MA programme in the area of digital fabrication. What’s so unique about this program? And how can students enroll in it?

Alevtina Chernikova: This MA program has been drafted by NUST MISIS’ Faculty of Non-Ferrous Metals’ Physical Metallurgy and FABLAB and is implemented using their facilities. This is Russia’s only MIT (Massachusetts Institute of Technology) certified FABLAB. The laboratory was initially established for working with gifted school students, as well as first-year and second-year university students. But we quickly realized that our competences are quite sufficient for launching MA-level programs.

The first students enrolled in 2015 and defended their MA theses in June 2017. The academic process hinges on various principles of the “conceive-design-implement-manage” project approach. NUST MISIS actively utilizes these principles at all education levels. Students take a compulsory graduation exam and submit their own projects. In other words, they design and assemble functional devices. Their projects are quite outstanding and interesting. As an example, I can mention a unique motorcycle headlight with a 120-degree light beam for illuminating motorways at night and a system for recognizing human faces based on neural networks.

In 2017, we enrolled 20 students in the program, and they will study free of charge on scholarship. We deliberately keep their numbers low because the highly flexible program is based on taking an individual approach toward each student.

Question: Whom do you want to join this exclusive MA program? What skills will graduates acquire?

Alevtina Chernikova: We are expecting high-scoring BA program graduates from technical universities who are interested in engineering sciences and who have accumulated substantial knowledge in the area of physics, chemistry, mathematics and information science. We plot individual educational trajectories on the basis of their fundamental training and encourage their interest in technical creativity. Our university will graduate experts capable of merging competences from various fields of knowledge and marketing new hi-tech goods. This program’s graduates are the engineers of the future.

Question: Where will students undergo their advanced training?

Alevtina Chernikova: The program is quite unique because its students independently work on their projects at a digital fabrication laboratory, mastering state-of-the-art equipment, technologies and materials. The educational process involves international experts, including university lecturers and professors who combine practical educational work with that in the area of design, architecture and computer modeling. These experts include architectural design maestro Giuseppe Fallacara, Associate Professor at Politecnico di Bari, and Jennifer Astwood, an associate professor of industrial design and head of an industrial design program at the University of Wisconsin-Stout.

In late June 2017, NUST MISIS opened the Kinetics Center for Industrial Prototyping of High Complexity, which will also serve as a production facility for MA students who undergo advanced training.

Question: What are the employment prospects of MA program graduates?

Alevtina Chernikova: Every university claiming the right to be a leading higher education institution has two ambitious goals: Formulating its own science-and-education agenda and addressing current challenges, as well as the business community’s requirements. For this purpose, the university cooperates closely with its business partners. Today, our graduates have received several job-placement proposals. One of our female MA students has designed an automated plant-growing module, and this invention is already used by the Bayer business accelerator. Another graduate works at a startup designing small and microcopters.

Our involvement in startups serves as an indicative example of the success of establishing small innovation companies on the basis of students’ research and development projects. Several years ago, students from our design bureau created a mathematical model of an Olympic torch for the 22nd Olympic Winter Games in Sochi. The torch was designed under the supervision of world-famous industrial designer Vladimir Pirozhkov who came to head the above-mentioned NUST MISIS Kinetics Center for Industrial Prototyping of High Complexity.

Later, these students set up their own Karfidov Lab small innovation company that marketed some new developments, including a coffee brewer for cars and a syringe for use by people without a medical education. Today, Karfidov Lab implements some large-scale projects on a par with major research and industrial organizations. One can mention numerous examples of dedicated young people developing new products and posting amazing results in this field. They clearly comprehend the all-out national challenges facing our society, and they can work on inter-disciplinary projects. The world is changing so quickly that we simply have to look into the future, in order to be able to train experts who will be in high demand tomorrow.

Question: What do you think about the laboratory’s technical-equipment levels? Do they meet international standards? And how much did this equipment cost?

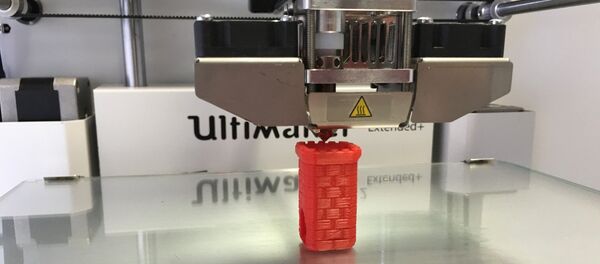

Alevtina Chernikova: In 2012, we established the digital fabrication laboratory, with initial expenses totaling $150,000. This made it possible to install all the main digital equipment models at FABLAB, including a CNC milling machine with a large working area, a laser cutting machine, a precision desktop CNC milling machine, a 3D printer and a cutting plotter. We expand the FABLAB structure each year, and we purchase the most advanced equipment.

Question: What projects have already been implemented at FABLAB?

Alevtina Chernikova: FABLAB conducts multi-formal activity. It conceives and organizes numerous events for children and adults. First of all, this includes educational projects for students from Moscow’s schools. FABLAB is actively involved in numerous career guidance events, allowing high school students to master digital fabrication and to acquire “maker” skills.

Cooperation with students is the next level and this has already been discussed in great detail. NUST MISIS’ MA program students regularly visit FABLAB facilities in Europe and the United States. Our FABLAB provides advanced training for our colleagues from digital fabrication laboratories all over the world. FABLAB opens its doors to city residents once a week; anyone can come here and realize his or her ideas. And, finally, FABLAB, for more than 12 months has been organizing Maker’s Faire, an international festival bringing together engineers-designers, artists, scientists, as well as simply talented and inquisitive people sharing their creative skills with others.

We implement a multitude of specific projects, including classic M.C. Escher art prints that have been materialized using lasers and acrylic; corrugated cardboard shades for LED lamps; a “Small House” which is a prototype functional structure manufactured using a digital machine and the “Tree of Creativity” replicating very complex elements with an irregular shape. The latter project was implemented at FABLAB under the supervision of Professor Fallacara who has been repeatedly lecturing at NUST MISIS, holding workshops and cooperating with MA program students.

Question: This means that the boundary between information and matter is being virtually eroded. What results will, in your opinion, this produce?

Alevtina Chernikova: Today, we are witnessing a new technological revolution called the Digital Revolution. The development of computers spurred initial changes. Breakthroughs in the area of calculations, communications and the Internet created a new wave of technological shifts. All this drastically democratized the process of obtaining, storing, processing and transmitting information. Digital technologies are becoming both industrial and personified.

This is how our world and our entire lives are changing. For example, highly important issues, including waste-free production and resource-saving technologies, top the global agenda. Earlier, we had to remove needless sections from molds while making a component. Experts are now able to grow various items exactly as needed. I believe, these paradigms will change hands even more actively in the future. Apart from responding to industrial requirements, we must anticipate such requirements so we can train experts for future careers.

Question: Is it true that a joke about a 3D printer that will print itself is no longer a joke?

Alevtina Chernikova: This joke has now become a reality. MIT and we are implementing a project called “Machines make Machines.” Robots are already replicating themselves. Moreover, laboratories replicating the human body’s organs with the help of 3D technologies are becoming a reality. This may seem like science fiction to us because we are not yet accustomed to these technological marvels, but such examples already exist.

Question: Will Russia lag behind in the area of digital technologies’ development?

Alevtina Chernikova: This will depend on us alone and on the extent to which we are ready to become involved in this process, as well as on our ability to train our current children for the future with its new challenges.

An expert who is in demand on the job market must quickly adapt to a modern and rapidly changing world. He or she must assess the situation on a large scale and be able to make decisions under duress. In other words, experts must be able to accomplish what a robot cannot do. They must also be able to study independently and to engage in permanent self-education. Therefore we need to provide students with basic knowledge and help each of them unlock his or her creative potential to the greatest possible extent, because tomorrow’s experts would otherwise be unable to build a successful career at a modern company.