Scientists from Russia Create New Method to Advance Explosion Welding Studies

© Photo : Nord Stream 2 AG

Subscribe

For the first time ever, scientists from Volgograd State Technical University together with colleagues from the Institute of Hydrodynamics of the Siberian Branch of the Russian Academy of Sciences were able to measure the temperature of metals during explosion welding.

According to them, the result will make it possible to seriously improve this technology, which is in demand in the rocketry, space and energy industries. The study was published in the journal Thermal Science and Engineering Progress.

Explosion welding is a method for obtaining various layered metal composites. Given the specific nature of this method, when it is used, there is no diffusion of metals, so a clear boundary remains between the layers, the scientists explained.

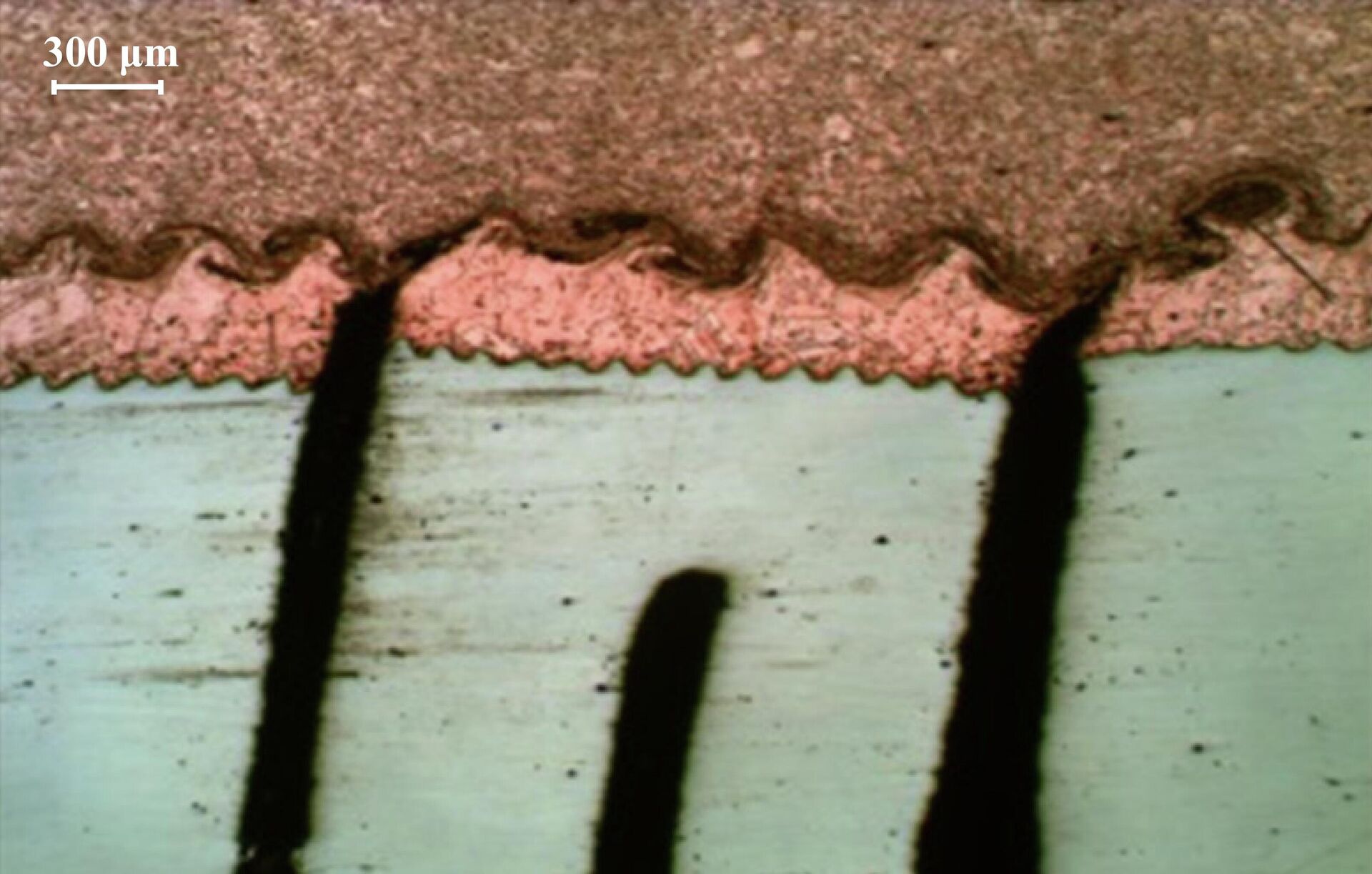

Such welding occurs due to the acceleration of metal plates by the explosion and their further collision at a certain angle. High pressure builds up at the point of impact, causing the metal to behave like a liquid. As a rule, waves form in the impact zone, and cumulation is observed in front of the contact point. The compound, according to scientists, is formed in the solid phase - that is, without melting.

In this way, it is possible to combine metal bodies with an area from several square decimeters to several square meters, experts noted. However, the wide application of this technology is hampered by the insufficient knowledge of its physical parameters, especially the temperature in the impact region.

Boundary of the joint of copper with constantan (copper-nickel alloy) welded by explosion

© Photo : Volgograd State Technical University press service

Scientists at the Volgograd State Technical University (VolSTU) - together with their colleagues from the Institute of Hydrodynamics of the Siberian Branch of the Russian Academy of Sciences - found a solution to this problem. According to them, the proposed technique makes it possible to accurately measure the temperature of the contacting metals during the explosion welding process, despite the fact that it takes millionths of a second.

“No modern thermometry method is able to take readings in such a short period of time, but we succeeded - we used the welded materials themselves as sensors. Combining copper and constantan by explosion welding, we got a thermocouple, which at the time of creation immediately generated an electrical signal, according to which we set the desired temperature,” said Sergei Kuzmin, First Vice-Rector of VolSTU and Corresponding Member of the Russian Academy of Sciences.

The obtained experimental data, according to experts, will allow for the better control of the welding process through the adjustment of the properties of the resulting composites. The materials created in this way are in demand today in the rocketry and space industries as well as the energy sector, the scientists noted.

“For the first time in the world, we experimentally determined the temperature of metals and the dynamics of its change at the boundary of the welded joint and in the adjacent heat-affected zone,” Kuzmin stressed.

The study was carried out jointly with specialists from the Institute of Hydrodynamics of the Siberian Branch of the Russian Academy of Sciences. In the future, the research team intends to find a complete solution to the thermal problem for explosive welding, that is, to describe all shock-wave and deformation processes at the boundary of the metals being welded, as well as the processes of heat and mass transfer and cumulation in the gap between them.