According to Tomsk Polytechnic University researchers, the accuracy of measurements when using a newly-designed neuronet-based method will surpass all the others. The results of the research have been published in the Journal of Nondestructive Evaluation.

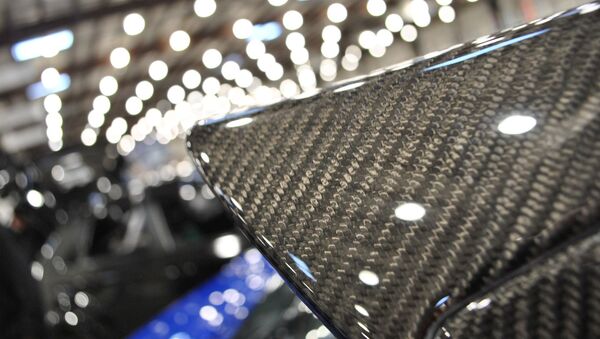

Fibre-reinforced plastic is a composite (material that consists of several components) made of polymer matrix and reinforced by fibreglass. It is widely used in the aerospace and automobile industries, energy production and other spheres, because it boasts a good hardness-weight ratio.

One of the wide-spread methods of non-destructive testing is infrared thermography, whereby materials are subjected to warming (usually with powerful optic lamps), and the surface temperature is controlled with a thermographic camera. If there are defects in a material, it will warm up and cool either slower or quicker, than an undamaged sample, the researchers noted.

According to them, this method allows to quickly control vast surfaces without contacting a material, with a good visualisation of the results, but the semi-transparency of fibre-reinforced plastic limits the use of the method of non-destructive testing.

“In non-transparent objects, the light is absorbed by the surface of a material and turns into warmth.The warmth from the surface then spreads deep into the material. Yet, in semi-transparent materials, part of lthe ight goes through them and is absorbed by the whole bulk of them. As a result, instead of surface warming we have it unevenly distributed. Hence, the methods based on the physics of surface warming are not working,” explained Alexey Moskovchenko, a post-graduate of the Engineering School of non-destructive testing and security at Tomsk Polytechnic University.

The researchers designed the new method of detecting the depth of defects in semi-transparent materials with the help of artificial neural networks. They say that the efficacy of the method depends on the quantity and quality of data used to “teach” a neuronet. It is possible to train a neuronet to work with a certain material and equipment to such an extent that the accuracy of measuring will be way ahead of all the rest of methods.

The authors of the research are incorporating the newly obtained algorithms into software, which is now being worked on in the laboratory. In the future, the scientists plan to modernise the algorithm in order to boost its accuracy, while also optimising the cost of the procedure and its timeframe.