Brought to you by the National Research Nuclear University MEPhI

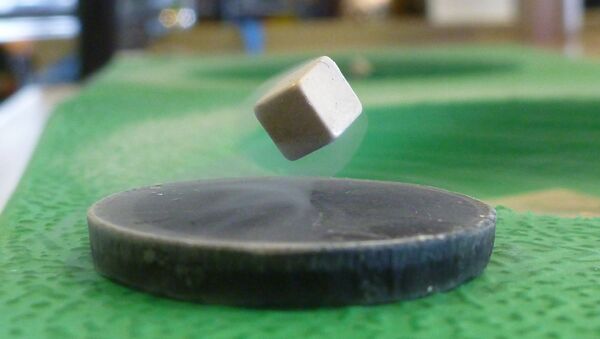

Today, various methods to produce tape wires from high-temperature superconductive materials are actively being developing around the world. They can transit to a state with zero electrical resistance at the temperature above the boiling point of liquid nitrogen (-196° C), opening up a wide range of applications for superconductors in engineering, energy and medicine.

READ MORE: Russian Universities are "Arming" Themselves in the Fight Against Center

The unique new method to control the paths of the tape composites was successfully tested at MEPhI’s Superconductivity and Magnetism Laboratory. It is based on precise calculations of the spatial distribution of currents flowing through a superconducting tape, which make it possible to identify defects as well as areas with lowered transport properties.

“We actively use the method we developed both to find out the reasons behind the defects in superconducting tapes and to solve practical tasks: for example, choosing homogenous areas in the tapes for subsequent use in real equipment. We, in our laboratory, continue to upgrade the experimental method to broaden possibilities and improve the test quality. In the near future, superconducting tapes will be tested with a magnetic field, transport currents and at various temperatures. The functions of the new method will provide both researchers and engineers with unique additional opportunities,” said Igor Rudnev, Professor at the Solid Bodies and Nanosystems Department, one of physicists who carried out the research.